Windows and doors are the heart and soul of a home. They let in natural light, frame views, facilitate the coming and going of people, add security, magnify space and allow the great outdoors to flow in. The aesthetics but also the functionality of windows and doors will determine the overall comfort and experience of a home so it’s important to choose the right windows from the get-go.

When remembering that windows and doors are essentially openings in an insulated wall, how these openings in the walls are installed and sealed will determine the level of insulation and energy efficiency of the home throughout the year.

Windows and doors typically make up a third of a home’s exterior yet still remain the most thermally inefficient exterior component leaving a home susceptible to thermal loss and gain. Building a home with high-performing, energy-efficient windows and doors will mitigate temperature fluctuations and boost insulation, and thermally broken windows are the perfect solution. In this article, we’ll explore how you can reduce the inefficiency of your windows to lower your power bills and maintain an even temperature in your home.

Energy efficient windows

When it comes to glass, double glazing has been the NZ Building Code H1 standard required for all new build homes since 2007. By late 2022 however, more energy-efficient solutions such as argon-filled, double glazed Low-E glass, will be the new minimum standard.

A high-tech glass option, such as Low-E, does wonders to keep a home well insulated. But the glass is only part of the window. For maximum performance, the framing chosen is equally as important as the glass and is what this article will cover in more detail as we explore the concept of a thermally-broken window.

Simply ticking the energy-efficient box by using energy-efficient glass only gets you halfway there. Thermally broken windows are the perfect means of achieving maximum energy efficiency from both the glass and the framing.

Before delving further into thermally broken windows however, let's first unpack standard aluminium framing.

Standard aluminium joinery

Across New Zealand and Australia, the frame of choice when it comes to windows and doors is aluminium - and for good reason!

Aluminium is an abundant and recyclable material that offers many benefits as the go-to window framing option. It’s low maintenance, UV stable, strong, durable, non-corrosive and long-lasting. Unfortunately, it has one significant pitfall – it’s highly conductive.

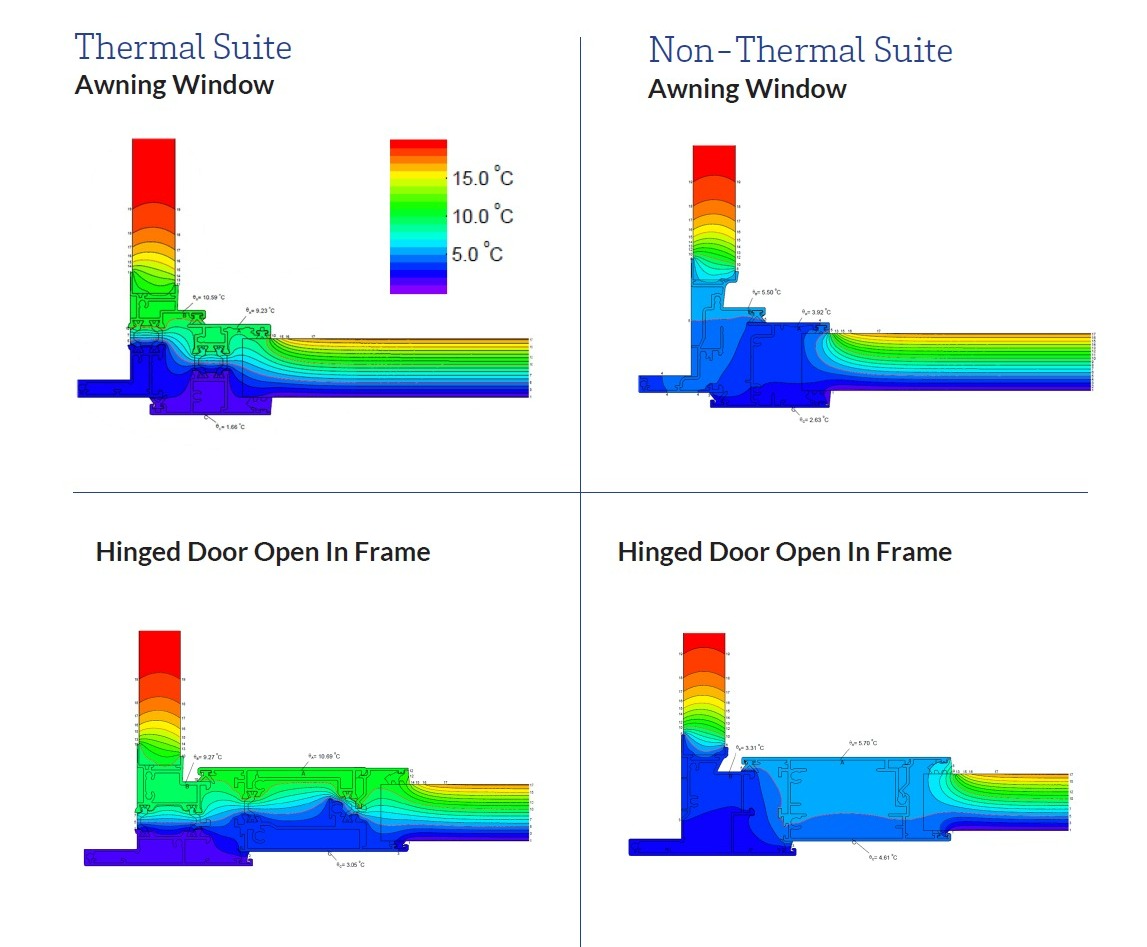

Heat, cold and noise can easily transfer through aluminium frames. With the aluminium frame exposed to both the outside and inside of the home, thermal energy is most easily lost through the framing, undermining the windows’ overall efficiency.

While the inefficiency problem is mitigated with quality glass solutions that help to build a strong thermal barrier, the conductive aluminium frames remain the weak link. The potential for condensation to build up around window or door frames remains a possibility as do other problems such as mould and the degrading of internal finishes when standard aluminium framing is used.

To overcome the disadvantage of conductivity when it comes to aluminium framing and prevent the temperature transfer between the interior and exterior of your home, a thermal break needs to be added.

Thermally broken windows

Thermally broken windows are essentially insulated window frames. Just like you wouldn’t build exterior walls without insulation, or skimp out on glazing, using insulated, energy-efficient window frames just makes sense.

Thermally broken windows work by adding a reinforced polyamide bar inside the framing separating the outside frame from the inside frame. This creates an insulated, continuous barrier within the frame that acts as a thermal resistor. This separation and insulation of the framing reduces the ability for heat to transfer between the interior and exterior of the house subsequently reducing the conduction of heat, cold and noise between the inside and outside of your home.

With the upcoming advancements to the Building Code H1 requirements, thermally broken aluminium window frames will become mandatory in housing and apartments, as it is phased in over the following 18 months, to achieve compliance with the new insulation standards. The placement of these window frames, within the line of insulation and the window frame junction with the wall cladding, becomes critical to maximise the benefits of these thermally improved windows.

How a thermal break works

Thermal energy can be transferred through materials that touch one another. By physically separating the external layer from the internal with a low conductivity material such as polyamide, the thermal energy pathway is broken hence a thermal break is created. By breaking the conductivity of heat through window framing with thermally broken windows, maximum energy efficiency is created.

While the widely used and well-known standard aluminium framing still provides many benefits to a home, thermally broken windows significantly out-perform them. Using thermally broken windows for your next build will maximise energy efficiency in the home providing excellent thermal performance that keeps your home well insulated all year round.

So if you’re en route to build a new home, or are an architect or developer seeking energy efficiency solutions for clients, opt for thermally broken windows and say adieu to condensation, reduce your carbon footprint, lower the power bill, and maximise the comfort of your future home as a result.

To discuss your next commercial, multi-residential or new build housing project, or for guidance on the how the building code changes could affect you, simply fill out the form below or contact us to speak with a member of the team for advice and solutions available.