When working on multi-residential projects, architects, builders, and developers face many critical decisions, including the choice of windows and doors. One key question is: Does your window supplier have full control of their supply chain? It’s a critical difference that can affect the success of your project. At UNO Windows & Doors, we explain why choosing a full supply chain manufacturer matters, ensuring consistent quality, faster delivery, and full compliance at every stage.

In this article, we’ll walk you through the differences between a fabricator and a manufacturer and explain why working with a full-supply chain manufacturer can make your project smoother, more efficient, and stress-free.

Fabricator vs Manufacturer: What Architects, Builders, and Developers Must Know

At a basic level, a fabricator assembles windows and doors from pre-manufactured components supplied under licence by a window system supplier. They don’t design or produce the materials themselves but, instead purchase the aluminium & main components from their system supplier and fabricate windows to match their interpretation of the plans. While they may be supplying a well-known brand, it introduces risks including, inconsistencies in quality in different locations around the country, depending on their processes, brings risks where the system supplier has details incorporated in plans that may not be able to be fabricated, potential delays in the supply chain waiting for system supplier to ship, & lastly the fabricator could supply & sometimes install a different product to what's been drawn in the details on plans because of the “disconnect” between the system supplier & the fabricator.

On the other hand, a full supply chain manufacturer like UNO Windows & Doors controls the entire process. From designing, sourcing, & stocking the aluminium profiles & components, testing & compliance to NZ standards, input into project design details, and R-value calculations, to overseeing the final manufacturing & delivery - everything is managed under one roof. This end-to-end control ensures that quality is maintained at every stage, one company is a point of contact, deadlines are met with precision, and the final product is built exactly to your project’s specifications. A full supply chain manufacturer can also assist with introducing value engineering to your project in the design stage because they are aware of how details, configurations, and materials used will affect the cost and streamlining of your project to completion.

5 Key Reasons to Choose a Full Supply Chain Manufacturer for Your Multi-Residential Project

![]() Consistency in Quality

Consistency in Quality

Multi-residential projects require consistent quality, especially when it comes to compliance with H1 regulations and ensuring optimal construction R-value performance. By working with a manufacturer, you can incorporate the actual as-built details in the design stage, reduce the risk of variances between the system supplier and fabricator, and guarantee that your windows and doors are produced to a high, uniform standard as drawn in the plan details.![]() Streamlined Communication

Streamlined Communication

With a fabricator, at different stages of the project, you may find yourself juggling multiple points of contact across different companies, which can lead to delays and confusion. A full supply chain manufacturer simplifies the process by giving you a single team to work with from start to finish -from concept to completion wherever your project is located. This approach ensures clarity and efficiency throughout your project.

![]() Avoiding Miscommunication and Design Setbacks

Avoiding Miscommunication and Design Setbacks

One of the common frustrations architects face when working with fabricators is the misinterpretation of plans. Architects often specify products by brand with the assistance of the system supplier, but once the project reaches the fabricator, sometimes it becomes clear that the details designed cannot be manufactured in reality as intended or drawn. This leads to delays, additional costs, rework of drawings, council amendments, and unnecessary stress. By involving UNO Windows & Doors early in the project, you gain the assurance that our team will collaborate with you to ensure all specifications are practical, achievable, and aligned with the manufacturing & where applicable the installation process from the start. This proactive approach helps prevent costly setbacks and keeps your project on track.

![]() Meeting Deadlines with Precision

Meeting Deadlines with Precision

Time is always of the essence, especially when you're managing large-scale multi-residential developments. A manufacturer who controls the entire process is better equipped to deliver on time, as they are not reliant on third-party system suppliers. They can potentially adapt production schedules to meet your needs, ensuring smooth project timelines and helping you avoid costly delays.

![]() R-Value & H1 Compliance

R-Value & H1 Compliance

An experienced full supply chain manufacturer like UNO understands the specific requirements of multi-residential projects in New Zealand, particularly regarding R-value for H1 compliance & optimisation. We calculate the construction R-values of each window and door unit using approved thermal modelling software, which in turn gives you the exact Construction R-value of your project. We recommend clients use the calculation method as a minimum, or the modelling method, for the most precise and reliable R-value assessments. This approach enables UNO to provide comprehensive assistance with R-value calculations, ensuring your project meets the exact thermal performance criteria. Plus, with UNO, you receive a certificate confirming the construction R-value, and the Solar Heat Gain Coefficient (SHGC) of the glazing, making H1 compliance straightforward during both the BC and CCC stages and giving you peace of mind throughout the process.

To make compliance even easier, you can access our free H1 compliance guides here.

Check our free guides to help you with H1 Compliance

Simplify Your Next Multi-Residential Project with UNO Windows & Doors

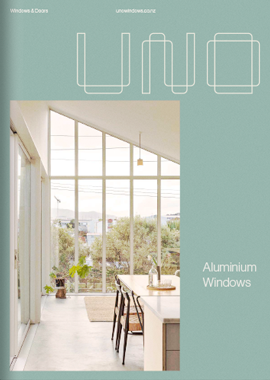

At UNO Windows & Doors, we take pride in being a full-supply chain manufacturer. From sourcing aluminium to using state-of-the-art CNC technology for precise manufacturing, we offer a fully integrated solution that ensures the highest quality in every product we deliver. Our aluminium joinery is designed to meet the unique challenges of New Zealand’s building environment, ensuring compliance, energy efficiency, and long-term durability for your multi-residential projects.

Need H1 Compliance or PS1 Help? Speak with UNO’s Experts Today

Ready to simplify your next project? Our team is here to help. Whether you need assistance with H1 compliance, producer statement documentation, or selecting the right configurations for your specific R-value requirements, we’re just a call or click away. Contact us today to discuss how our aluminium windows and doors can deliver a reliable, hassle-free solution for your multi-residential project.

Conclusion: Why Full Supply Chain Manufacturing is the Smarter Choice for New Zealand Projects

Choosing a full supply chain manufacturer over a fabricator for your windows and doors in New Zealand is more than just a decision about product sourcing, it’s about choosing a partner that gives you peace of mind. Learn more about why developers and architects choose UNO to deliver consistent, end-to-end window and door solutions for multi-residential projects.

By opting to work with a full-supply chain manufacturer like UNO Windows & Doors, you ensure that your project is managed with precision, that deadlines are respected, and that the final product is delivered with seamless quality from concept to completion.