When specifying windows, every decision holds significant weight. The choice of windows can dramatically influence the costs, aesthetics, functionality, and energy efficiency of a building, which makes navigating the myriad of choices increasingly daunting.

When you’re specifying your aluminium windows and doors, this article will be your compass. We cover everything from frame types to costs to aluminium finishes to specs advice.

1. Window frame types

When choosing your window frames, start by choosing the best window frame material. Common options include wood and uPVC but these are more likely to deteriorate over time when exposed to the elements.

Aluminium, on the other hand, is strong, durable, and low maintenance. It’s also recyclable, corrosion-resistant, UV-resistant, and lightweight. In aluminium frames, you can also include a thermal break to improve energy efficiency.

2. Window costs

When purchasing aluminium windows, understanding the financial implications is paramount. As a builder, it's crucial to provide your clients with accurate information and estimates. Costs vary depending on size, configuration, glazing options, and the powder coat finish so you must be aware of these factors upfront.

Fortunately, as an integrated supplier, we can offer competitive pricing because we bundle our services. We offer design consultation, H1 calculations, manufacturing, and installation as a streamlined, package deal. From design to procurement to delivery to installation, this will often reduce the overall window costs.

3. Configurations and customisation

Aluminium windows come in a range of configurations to suit diverse architectural styles and functional requirements. Whether it's casement, sliding, awning, or something else, it's important to consider space constraints, hardware costs, ventilation needs, and aesthetic preferences when selecting the appropriate configuration.

4. Window suppliers

Time is of the essence in the construction industry and delays can be detrimental to your project timeline and budget. When procuring aluminium windows, you should collaborate closely with your suppliers to establish realistic lead times and delivery schedules.

As an end-to-end supplier, we can offer the advantage of streamlined communication from the design stage through to the project management stage. This minimises the risk of delays and ensures timely delivery of the windows to your job site. Additionally, by leveraging our process and software we can enhance accountability throughout the procurement process.

Clear communication and documentation are essential when finalising window selections. At UNO, our proven workflow helps you firm up your selections promptly, including wall thicknesses, door directions, flashing sizes, glass types, and powder coat colours. Submit a tender for your project to experience it for yourself.

5. Powder coat colours and finishes

The aesthetic appeal of aluminium windows is greatly influenced by the choice of colours and finishes. We have created our Key Colour Range, which covers 80-90% of all projects we complete.

As a builder, you should guide your clients through the selection process, considering factors such as architectural style, surrounding environment, personal preferences, and the cost of the powder coat. To simplify the process, you can order sample swatches here.

Your architects may also provide 3D artist impressions of your build to facilitate decision-making and allow you to envision how different colours and finishes will complement your project.

Explore the best NZ architects for H1 Projects

6. Glass types

Glazing options play a crucial role in the energy efficiency and comfort levels of a building. Always consider the various types of glass available, including low-E coatings for energy efficiency and laminated glass for enhanced security and noise reduction.

Energy performance ratings such as U-values and Solar Heat Gain Coefficients (SHGC) provide valuable insights into the thermal efficiency of windows, helping you make informed choices that align with your sustainability goals and budgetary constraints.

7. Manufacturing capability and project portfolio

It is important to review the window supplier you choose so always check out their completed projects, manufacturing machinery, and reviews from previous clients. This will highlight any potential issues before signing a contract. You can read more about the UNO team on our About Us page, browse our image gallery, or submit a tender to make an informed decision.

8. Framing plans

Framing plans serve as blueprints for precise window measurements and, using our proven process, we can ensure a seamless fit within the building envelope. At UNO, we can work with framing plans, precast shop drawings, and steel shop drawings to confirm your final window sizes.

As integrated suppliers, we can provide invaluable expertise in interpreting framing plans and recommending solutions that optimise both aesthetic appeal and functional performance.

9. Choosing your supplier early

When specifying windows and doors, select your supplier as soon as possible. This allows your suppliers and architects to start the process sooner and enables everyone involved to plan their workflows in alignment with your project timeline. Organising your joinery specs ahead of time also gives you the chance to tap into the expert industry knowledge of your manufacturers.

At UNO, our team has over 15 years of design and production experience which is well worth taking advantage of. To specify your products, contact us, check out our Technical Resources page, or see the top architects for H1 window specifications.

10. H1 calculations and energy efficiency

In light of the recently updated H1 standards, we recommend using the calculation method as a minimum, provided the glazing area does not exceed 40% of the total wall area. This can result in substantial project savings in other areas, such as roof insulation or wall insulation.

For the step-by-step calculation method, download our H1 guide. When you’ve completed the calculations, send us your plans for assessment, including elevations, floor plans, and the window schedule. Our experts will let you know the next steps and provide recommendations tailored to your project.

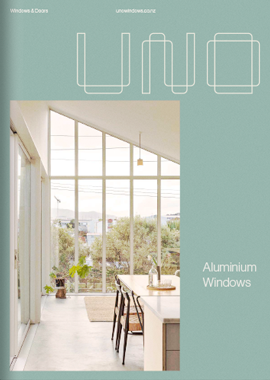

Aluminium windows in NZ

At UNO Windows & Doors, we know the importance of a seamless, well-managed project. As your integrated supplier, it’s our goal to organise everything you need when you need it to ensure you’re always meeting your deadlines.

To get started with your project, download our technical files or request colour samples to inspire your clients. Alternatively, you can download the following product brochures for more information: