Understanding R-values is key to designing energy-efficient buildings and selecting adaptable and efficient end-to-end window & door solutions that support H1 compliance in New Zealand. An R-value indicates how well insulation resists heat flow; higher values mean better thermal performance. Knowing the required R-value for your project's walls, floors, roofs, and windows is essential to meet New Zealand Building Code H1 standards and improve occupant comfort.

What is an R-value?

R-values describe how well insulation material resists heat flow. They can differ depending on thickness, the direction of the heat flow, and composition. The higher the rating, the more thermal insulation and the better the performance.

As with many insulation materials, 'thicker' doesn't necessarily mean better insulators, since some thinner materials might have better thermal resistance. For example, while 50mm polystyrene is considerably thinner than 80mm thick glass wool, both have an R-value of approximately 1.5.

What’s the difference between R-values and U-values?

While R-value measures thermal resistance through a material, U-value measures thermal conductivity. U-value ratings generally range from 0.1 (very little heat loss) to 1.0 (high heat loss). So, if heat transfer through a certain material is minimal, its U-value will be low and its R-value will be high, making it a high-performing insulator.

While both values are used as ratings of energy efficiency, a U-value measure is often related to insulated glass units, while an R-value is the inverse of the U-value and is used for a specified performance rating applicable across most insulation units. The R-value, being the inverse of the U-value, is converted as 1/R = U, and 1/U = R.

How to calculate R-values

Calculating the R-value of a window is normally performed with thermal modelling software in accordance with New Zealand and European standards. This software takes into account the U-values and areas of each material comprising the window and calculates an overall U-value for the complete window as a combined whole. Our design team utilise this thermal modelling software to ensure compliance with the NZ Building Code H1 requirements.

There are three recognised methods under the H1 building code to calculate Construction R-values: the Schedule Method, the Calculation Method, and the Modelling Method. At UNO, we recommend using the Calculation Method as a minimum. It provides a more accurate and project-specific result than the Schedule Method.

When using the “calculation method”, you can use the tool from the NZBC online calculator to input all the square metre areas and construction R-values for each component. This will advise you of the heat loss from your building compared to the reference building, and if you are compliant with the code.

This also lets you play with the insulation numbers and gives you the ability to adjust and reduce insulation R-values in other areas, such as roof insulation or slab edge insulation, potentially saving you money.

Process to get UNO to assist with R-values:

- Send your plans (Elevations, floor plan & window schedule) to spec@unowindows.co.nz

- We will then supply the construction R-value report, as well as certification to assist with your compliance with the Building Code.

New Zealand's current insulation standards

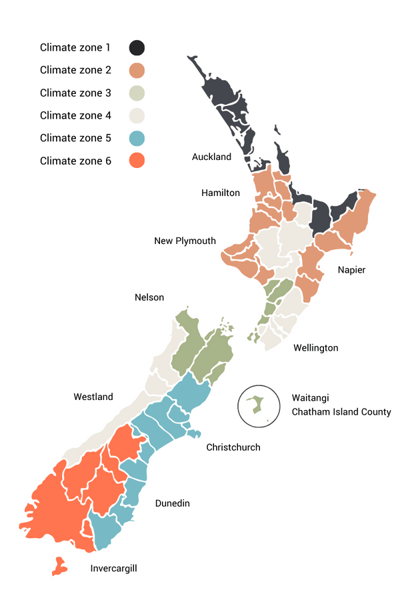

New insulation requirements under clause H1 of the Building Code are now fully in effect across all six climate zones. These are the most significant insulation updates in over a decade, and all new residential and commercial buildings under 300m² must now comply.

The updated standards ensure homes and small buildings are warmer, drier, and more energy-efficient, reducing energy use by up to 40%, cutting heating bills, and contributing to New Zealand’s carbon-neutral goals.

Explore our ultimate H1 guide for architects

R-value requirements for New Zealand

In terms of building code requirements, there are six recognised climate zones in New Zealand based on altitude, climate and average temperature. Zones 1-2 consist of warmer coastal areas and will require less insulation, while in zones 5-6 with colder alpine areas in the South Island the insulation requirements are significantly greater.

What R-value do I need?

R-value requirements differ depending on the building component: walls, floors, ceilings, and roofs all have their own minimums under the updated Building Code. These requirements are now fully in effect across New Zealand’s six climate zones. To make compliance easier, we've summarised the current standards so you can confidently specify the right insulation levels for your project.

Floors

Underfloor insulation plays a key role in ensuring buildings remain warm, energy-efficient, and comfortable. Under the current H1 Energy Efficiency requirements, all new builds must meet increased R-values tailored to each climate zone and floor type.

For slab-on-ground floors:

- Zones 1–4 require a minimum R-value of 1.5

- Zone 5 requires 1.6

- Zone 6 requires 1.7

For other floor types (e.g. suspended floors):

- Zones 1–3 require an R-value of 2.5

- Zone 4 requires 2.8

- Zones 5–6 require 3.0

These upgraded standards are now fully enforced and are designed to reduce heat loss through the floor, which is especially critical in colder regions of New Zealand.

Walls

Since an average of 22% of heat is lost through uninsulated walls, all new build houses across the country will be required to have an R-value of 2.0 or higher when the changes come in.

Roof

More heat escapes from the roof than any other part of a house, making it the most important to insulate. With the new changes, the required R-value is dramatically increasing from 3.3 to at least 6.6 for all new build houses.

Windows

Under the current New Zealand Building Code, all windows in new build houses must be double glazed, with minimum R-values ranging from 0.46 to 0.50, depending on the climate zone. While double glazing has a positive impact on energy efficiency, it's no longer enough on its own glazing is just one part of the full window system.

To achieve optimal thermal performance and meet H1 compliance, both the joinery and glass specification need to be considered.

For example, Low-E glass improves insulation by reflecting heat back into the room during winter and deflecting it outside in summer. When combined with double glazing, argon gas, and thermally broken aluminium frames, this system creates a high-performance barrier that significantly improves insulation and comfort year-round.

For more on high-performing glazing solutions, explore our full range of energy-efficient glass options.

Discover energy-efficient glass

Current R-value Requirements for Windows

The updated R-value requirements for windows are now fully enforced across all six climate zones in New Zealand. These standards play a crucial role in meeting H1 Energy Efficiency compliance and ensuring new builds achieve better thermal performance.

Minimum R-values by zone:

- Zones 1 and 2 – R-value of 0.46

- Zones 3 and 4 – R-value of 0.46

- Zones 5 and 6 – R-value of 0.50

These values apply to the entire window unit, including both glazing and joinery. Achieving these targets typically requires a combination of double glazing with Low-E coatings, argon gas fill, and thermally broken aluminium frames, a system that supports better energy retention and greater year-round comfort.

Want to compare materials? We’ve broken down the performance of aluminium vs uPVC window systems to help you make the best call for your multi-residential project.

Read more: Aluminium vs uPVC – What’s Best for Multi-Residential?

Increasing the R-value of windows

To meet these new standards, depending on your climate zone, it’s possible you’ll need to opt for some of the following solutions. To help you decide which one, we’ve summed up all the pros and cons of each.

Timber window frames

Many homes in New Zealand have timber window frames and since wood is a naturally effective insulant and is relatively sustainable, it’s easy to see why. However, the high cost and constant maintenance required with timber frames have meant they’ve become a far less common option in new build houses.

UPVC window frames

Window frames made of UPVC are reasonably durable, easy to maintain, however it they will need replacing sooner than aluminium. UPVC is a type of plastic that’s weather resistant, soundproof, and highly insulating. With a standard R-value of 0.41, it is an effective choice, but as it is largely imported from Europe this can lead to hidden costs or delays which is why it isn’t widely used in New Zealand.

Compare aluminium vs uPVC window systems

Thermally broken aluminium windows

While standard aluminium window framing has been known for its higher levels of conductivity, however thermally broken windows are a different story altogether. Thermally broken frames are reinforced with insulating polyamide bars which separate the inside frame from the outside frame. This performs in the same way as argon-filled, double glazing with a thermal spacer bar, providing a thermal break and therefore reducing the heat transfer between the exterior and interior. This makes them an energy-efficient, extremely durable, sustainable, and low-maintenance option as well as the most streamlined design.

How to achieve higher R-values for aluminium windows

Since each project is unique, there is no one-size-fits-all maximum R-value. However, let’s consider an example where the total area for windows and doors is approximately 35 square metres, & had configurations as shown in the below images. Using the UNO thermal window suite and a double-glazed Low-E product with a Ug-value of 1.1, we can achieve a construction R-value of R0.61.

According to the schedule method, only R0.5 is possible, meaning our products offer a 22% higher R-value in this example.

Taking it a step further, we can explore other double-glazed Low-E options, such as a product with a Ug value of 1.0. The same project could achieve an R-value of R0.65, which is 30% higher than the schedule method in this example.

Furthermore, if we consider a triple-glazed option with a Ug-value of 0.6, we could achieve an R-value of R0.83. This is 33% higher than the schedule method, which notes Rw 0.62 in this example.

Please note that it is crucial to use our specialised software to verify the sizes and configurations throughout the building.

Want to understand how window R-values influence cost and compliance strategies?

Explore our breakdown: Ideal R-Value vs. Window Costs

If you're planning a new project, our team can help you specify the right window systems to meet R-value targets, streamline compliance, and reduce future rework.

See how UNO helps streamline H1 compliance

Contact the UNO team for advice